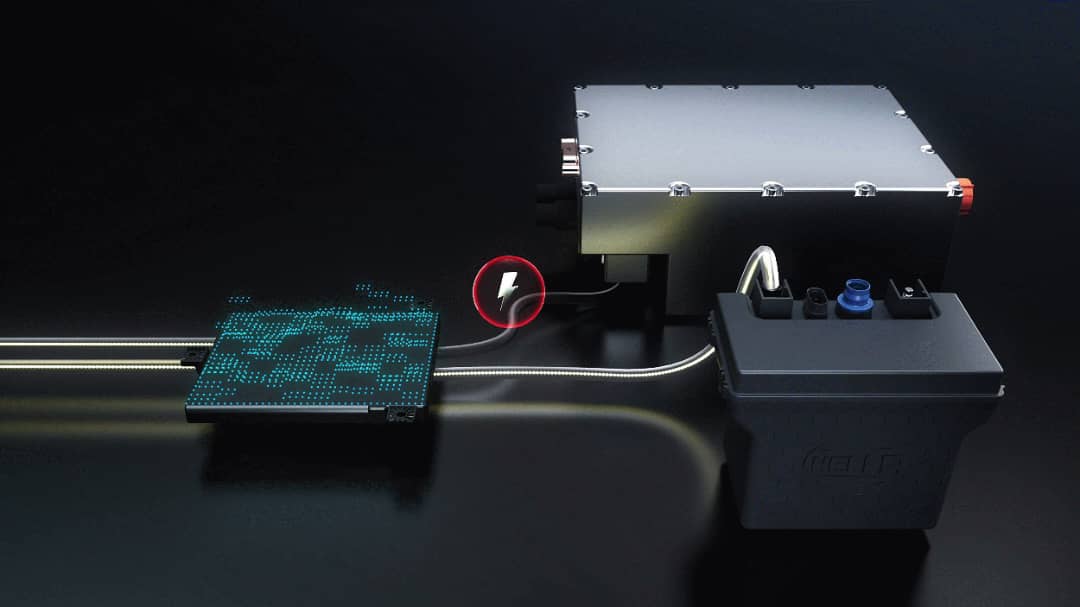

Global automotive supplier FORVIA HELLA has begun large-scale production of its Intelligent Power Distribution Module (iPDM), a breakthrough technology designed to modernize how vehicles manage electrical power.

Recently entering series production for a German carmaker, the iPDM is regarded as a crucial enabler for the next generation of connected and automated mobility.

The iPDM sets itself apart by replacing conventional fuses with electronic fuses, or “eFuses.” Traditional fuses burn out after a fault and require replacement, while eFuses use software control to monitor power flow in real time.

This allows the system to detect potential hazards, such as overheating cables, and respond immediately without causing a complete power loss. Such a fail-operational capability is vital for automated driving, where critical systems like steering, braking, and sensors must remain active even during electrical faults.

Also Read: http://Semarchy Announces Microsoft Fabric Integration

As cars evolve into software-defined machines, manufacturers are moving from decentralized electrical setups with over 100 control units to zonal architectures.

The iPDM fits seamlessly into this shift, providing centralized, intelligent power management. Its design also reduces wiring harness weight by as much as 25%, improving energy efficiency and simplifying production processes.

FORVIA HELLA’s innovation has already earned industry accolades, including the CLEPA Innovation Award and recognition as a PACEpilot “Innovation to Watch.”

With mass production now underway, FORVIA HELLA is positioning itself at the forefront of control electronics. The company has secured orders exceeding €1 billion for its iPDM and related modules, highlighting growing industry demand.

Beyond efficiency gains, this advancement strengthens energy safety and management in vehicles, paving the way for the widespread adoption of autonomous driving technologies.

By Victor Georgewill