Samsung Electronics has unveiled plans to spend Won133tn ($115bn) over the next decade on its non-memory chip business, aiming to overtake TSMC as the world’s biggest maker of made-to-order computing chips, according to Financial Times.

The South Korean technology group said on Wednesday it would invest Won11tn ($9.6bn) a year through 2030 on developing logic chips and its contract chipmaking business.

The massive investment — almost as much Morocco’s $118bn GDP last year — is part of efforts by Samsung to diversify away from the volatile memory chip business, which is currently the company’s primary income generator.

Samsung, the world’s largest memory chipmaker, this month projected a 60 per cent drop in first-quarter operating profit due to falling microchip prices.

“The investment plan is expected to help the company to reach its goal of becoming the world leader in not only memory semiconductors but also logic chips by 2030,” Samsung said.

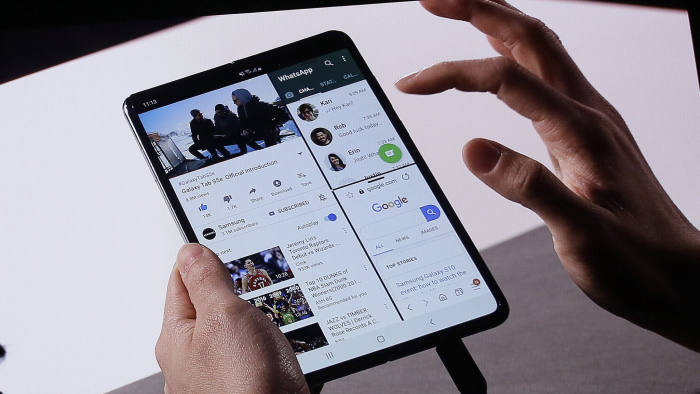

Memory chips store data for personal computers and mobile devices, while logic chips are key processors that operate those gadgets.

About Won60tn of the Won133tn will go towards boosting production infrastructure, with the rest invested in domestic research and development, the company said. The total amount is about three times Samsung’s 2018 net profit and a little more than half of its sales last year.

Samsung is keen to tap into rising demand for outsourced production of high-performance computing chips to run new applications such as the internet of things and autonomous driving. The smartphone has made contract chipmaking a huge global business, with Apple paying Taiwan-based TSMC billions of dollars a year to build the processors that power its iPhones.

Although Samsung dominates production of the memory chips, it has struggled to compete with TSMC, the world’s largest foundry, in contract chip manufacturing.

Samsung is the second-largest foundry with a 19 per cent market share, well behind TSMC’s a 48 per cent, according to market researcher TrendForce.

Analysts said Samsung had an opportunity to catch up with TSMC with next-generation process Extreme Ultraviolet Lithography technology that would enable it to make smaller, faster chips at lower cost. Samsung is building a $5.6bn foundry plant with EUV equipment to start mass production of its most advanced chips in 2020.

The two companies have been competing to cram more power into smaller chips in search of speed and cost savings. Analysts said Samsung needed to expand its foundry product portfolio to attract more second-tier customers, in addition to just a handful of big-name clients, to catch up with its Taiwanese rival.

Demand for contract manufacturing would surge as 5G penetration increases, said Kim Young-woo, an analyst at SK Securities, adding that only TSMC and Samsung had the most advanced technology required to produce the smaller but faster and more powerful 7-nanometer chips necessary for 5G devices.

“Samsung is seeing this year and next as an inflection point to get ahead in process technology. But technology alone will not be enough to steal customers from TSMC. It needs to show more track record in this field,” said CW Chung, head of research at Nomura in Seoul.